Angel Beverage Machinery is professional in producing liquid filling and packing machines.

Shrink Wrapping is a process that involves the application of temperature sensitive films. When heat is applied to the film it shrinks tightly to whatever it is covering. Shrink wrapping equipment is available for a variety of product sizes and in both automatic and semi-automatic formats. we can help you find the right shrink wrap machines that are tailored to your operation’s unique needs.

L type film shrink packing machine | |

Model | MB-400 |

Applicable Container | Plastic bottle, Glass bottle, Tins and Cans |

Maximum package size | 400×300×400 (height) mm |

Largest Bottle diameter | 450×300×400 (height) |

Length of heat-sealing knife | 700mm |

Shrinkage temperature | 130-260℃ |

Contraction time |

|

Heat sealing and cutting temperature | 150-200℃ |

Maximum production speed | 600 BPS/h |

Number of bottles per package (round or square) | |

4 columns 4 x 6 4 x5 applicable bottle size | 4 x 4 Ф 40 - Ф 70 mm |

3 columns 3 x 3 applicable bottle size | 3 x 4 Ф 70 - Ф 98 mm |

2 columns 2 x 3 bottle diameter | 2 x 4 Ф 98 - Ф 140 mm |

1 column 1 x 2 x 1 applicable bottle diameter | 1 x Ф140 - Ф300 mm |

Full automatic shrink packaging machine can not only be solely used, but used simultaneously with other equipment to form packaging production line. It can automatically array, aggregate and align PET beverage bottle or other similar articles, then package it with shrinking film, finally produce finished products after shrinking by heating, cooling and forming. The packaged product is firmly bound with excellent appearance, which can be opened conveniently. Therefore, it is widely used in industries such as foodstuff, medicine, chemical and other light industrial products.

Applications:

Plastic bottles

Suitable: Water, juice, soft drink etc Bottle

Type : Round / Square / Unique

Shrink film : PE, PP, PVC, POF etc...

Glass bottles

Suitable : Beer, wine, brandy, vodka

Bottle Type : Round / Square / Unique

Shrink film : PE, PP, PVC, POF etc...

Tins & cans

Suitable : Daily chemical products

Bottle Type : Round / Square / Unique

Shrink film : PE, PP, PVC, POF etc...

PLC control system

1. Operating through touch screen with friendly interface convenient for man-machine communication and operation.

2. The inductive switch controls the membrane transfer system to reliably adjust and control membrane transfer length with less loss

3. With automatic functions of bottle transfer and arrange, membrane packing, sealing and cut, shrinkage, cooling and shaping, etc.

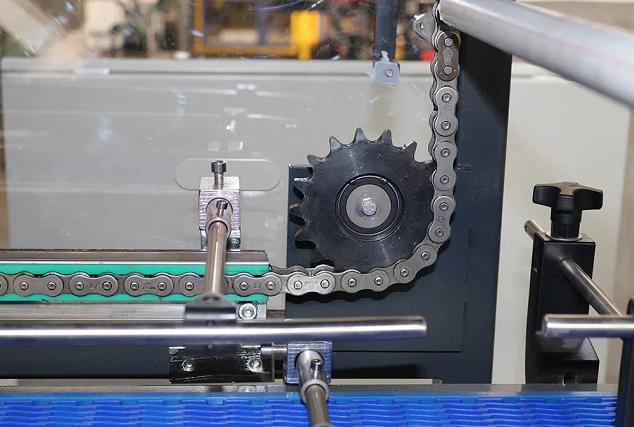

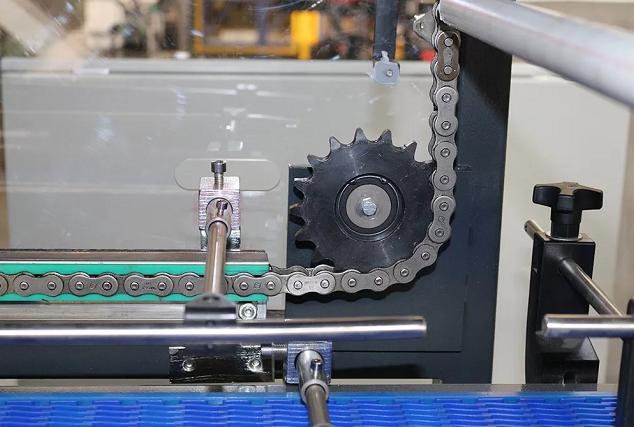

Transfer system

1. Adopting solid steel bar wrapped with imported silicone pipes, chain bar conveyor is durable in use.

2. All the transfer system is controlled by frequency changing devices with stable and smooth transfer speed.

3. The imputing position can be adjustable precision base on the size of products.

Adopting solid steel bar wrapped with imported silicone pipes, chain bar conveyor is durable in use.

Shrink tunnel

1. Super cooling system to ensure the perfect shape of products quickly after shrinking.

2. It adopts imported double wind driving motor, with even heat wind volume in furnace and the beautiful shrinking effects.

3. Adjustable hot wind stream guidance recycling structure in furnace makes equipment more power saving.

4. The size of tunnel can be customized for your request.

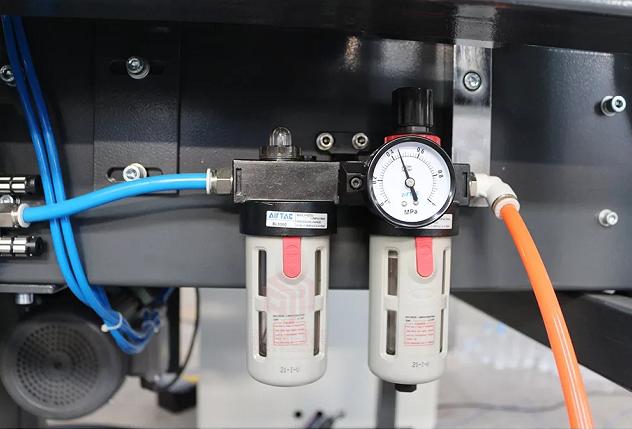

Electrical Equipment

1. Imported frequency converter, stepless speed regulating.

2. Adopting Mitsubishi PLC programmable logic controller, realizes mechanics, electric, and pneumatic integration.

Imported AC contractor, the temperature be controlled by automated.

List of main components:

Name | Brand | Original |

PLC Control |

| Germany |

Frequency converter |

| Germany |

Touch screen |

| Germany |

Mechanic overload |

| Germany |

Breakers |

| Germany |

Photocell switch |

| Japan |

Proximity switch |

| Japan |

Bearing |

| Japan |

Pneumatic components |

| Germany |

Pump |

| China |

Main drive Motor |

| Switzerland |

Features of linear type shrink wrapping machine:

1. The appearance is simple and beautiful, the structure is novel and unique, and the maintenance is convenient.

2. Adopt pneumatic expansion to support the film roll, electronic induction film transport, stable film delivery, fast and convenient film change.

3. The whole machine is designed as a linear model with linear bottle feeding and packaging. The structure is mature and stable. It is an alternative to the vertical feeding film packaging model and is more suitable for packaging needs of a variety of bottle types.

4. Adopt pneumatic expansion to support the film roll, electronic induction film transport, stable film feeding, quick and quick film change.

5. The heat shrinking and cooling integrated machine, the shrinking machine is equipped with independent cooling channels, which can quickly cool and shape the product surface after the film package, with better fastening force, which is beneficial to palletizing and handling

6. The shrinking chamber adopts unique circulating air supply technology to realize multi-directional air volume control technology, adjustable wind speed and adjustable air outlet position, which greatly improves the shrinking effect.

7. The equipment has a compact structure, a small footprint, and is easy to maintain.

8. Modules can be added to realize the color film function, which is a highly cost-effective single-piece wrap film shrink packaging machine.