Angel Beverage Machinery is professional in producing liquid filling and packing machines.

We offers a full range of shrink sleeve label applicators for low, medium, and high-speed production environments. All of our shrink material applicators are capable of performing up to five key sleeving applications: Full body sleeves, Full body over-the-cap sleeves, Partial body sleeves, Tamper evident bands, Multi-packs etc. Angel machine also offers wide label format models capable of handling label widths up to 900mm. our shrink sleeve label applicators and machine systems are used in a wide variety of industries including fluid milk, craft beer, ready-to-drink beverages, cosmetics, home care products, and personal care products. Their flexibility and reliable performance make them one of the best values in the shrink sleeving industry.

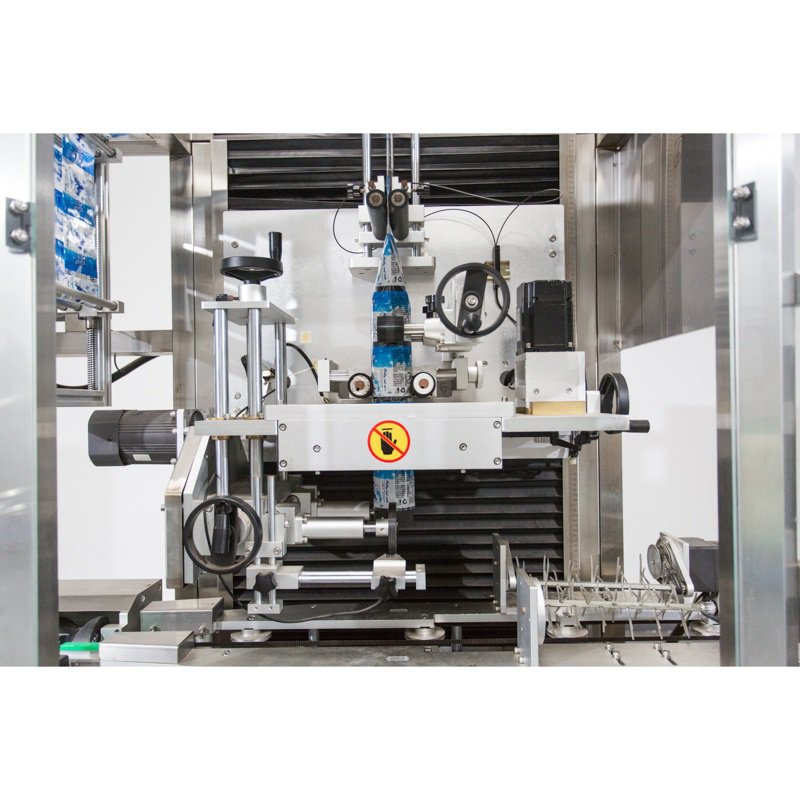

Working principles of sleeve labeling machine:

A sleeving machine shoots heat shrinkable plastic sleeves over bottles as they pass by on a conveyor. The sleeves are supplied as lay flats on reels, printed with label information. The fascinating part of a sleeving machine is how it opens the lay flat into a cylinder and then cuts the labels to the correct length at high speed.

Shrink labeling is a two-step process. First, a heat-shrinkable plastic sleeve is dropped over a bottle as it moves by on a

conveyor. Second, the sleeved bottle is conveyed through a heat tunnel that shrinks the label to a snug wrinkle-free fit. A shrink tunnel must subject the bottle to the correct amount of heat for the right length of time. Shrink labeling systems can achieve speeds in the range of 150-400 bottles per minute depending on the sleeving machine model purchased.

Technical Parameter | |||||

Model | SHX-150 | SHX-250 | SHX-250D | SHX-300 | SHX-400 |

Capacity | 150 bottles/min | 250 bottles/min | 250 bottles/min | 300 bottles/min | 400bottles/min |

Label heights | 30~250mm | 30~250mm | 30~250mm | 30~250mm | 30~250mm |

Bottle diameter | 28~125mm | 28~125mm | 28~125mm | 28~125mm | 28~125mm |

Thickness of label | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm |

Label material | PVC/ PET | PVC/ PET | PVC/ PET | PVC/ PET | PVC/ PET |

Machine weight | 550KG | 600KG | 700KG | 800KG | 950KG |

Overall machine size (mm) | 2100x850x2100 | 2100x1100x2100 | 3200x 1200x2070 | 2600x 1100x2200 | 2600x 1100x2200 |

Steam heat shrink tunnel

Tunnel provides the support for making hot sleeves which can be readily wrapped on products or containers. The tunnels are available with different mechanisms which can be chosen based on the wrapping material and its compatibility with the type of heat produced inside the tunnel. Consumers can choose hot steam tunnel or electric heat tunnels as per the labeling material texture

and compatibility.

Steam Generator

The steam pressure is 3.5 bar, then open the steam hand valve to about 45 degrees, let the steam shrinking furnace heat up, and observe the temperature gauge on the shrinking furnace at 95-100 degrees.

List of main components:

Name | Brand | Original |

PLC Control |

| Germany |

Frequency converter |

| Germany |

Touch screen |

| Germany |

Mechanic overload |

| Germany |

Breakers |

| Germany |

Photocell switch |

| Japan |

Proximity switch |

| Japan |

Bearing |

| Japan |

Pneumatic components | | Germany |

Pump |

| China |

Main drive Motor |

| Switzerland |

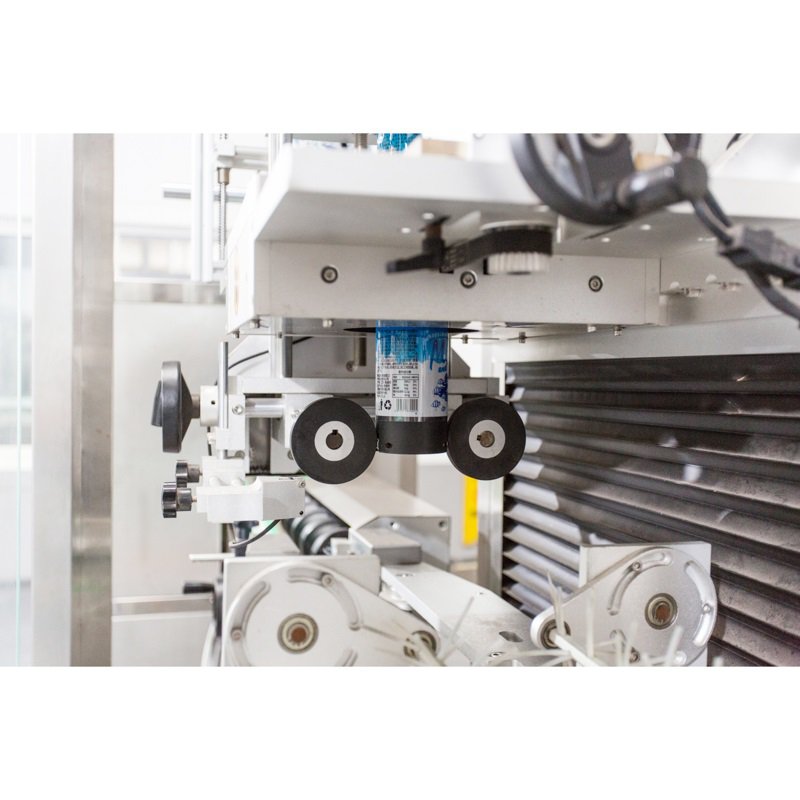

Working principles of sleeve labeling machine:

A sleeving machine shoots heat shrinkable plastic sleeves over bottles as they pass by on a conveyor. The sleeves are supplied as lay flats on reels, printed with label information. The fascinating part of a sleeving machine is how it opens the lay flat into a cylinder and then cuts the labels to the correct length at high speed.

Shrink labeling is a two-step process. First, a heat-shrinkable plastic sleeve is dropped over a bottle as it moves by on a

conveyor. Second, the sleeved bottle is conveyed through a heat tunnel that shrinks the label to a snug wrinkle-free fit. A shrink tunnel must subject the bottle to the correct amount of heat for the right length of time. Shrink labeling systems can achieve speeds in the range of 150-400 bottles per minute depending on the sleeving machine model purchased.